THE MELTMINDER

A PUBLICATION BY BENTON FOUNDRY, INC.

Web Site: www.bentonfoundry.com

Congratulations to Ryan Keeler (above), Benton Foundry’s 1st shift Employee of the Quarter. Ryan works in the Melt Department as an Assistant Supervisor. He has worked at the foundry since January 2020. Ryan previously worked in the core room as a core machine operator. He lives in Benton with his wife Miranda and their two children. Ryan enjoys hunting, fishing and spending time with is family in his spare time.

Great Job!

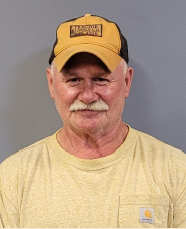

Congratulations to Andy Spencer (below), Benton Foundry’s 2nd shift Employee of the Quarter. Andy works in the Core Room as an Assistant Supervisor. He has worked at the foundry for 25 years. Andy has held many positions in various departments over the years. He lives in Shickshinny with his wife Amy. He has three children and 1 grandson and he enjoys fishing, NASCAR and spending time with his family when he isn’t working.

Great Job!

Other nominees included: Geremias Osorio, Gilberth Aleman, Joe Vanderlick, Roxi Ortiz, Jorge Serrano, Ed Cole, Olivia Schechterly, Debbie Clocker, David Straub, Ed Evans, Stanley Shuleski, Chris Diltz, Bobby Campbell and Xenia Ponce.

B

enton Foundry held its 29th annual company picnic on Saturday, August 9th at Knoebels. It was a perfect summer day with lots of sun and fun. We had a nice turnout, with over 400 attending. There were lots of great prizes, many of which were donated by Benton’s vendors. We enjoyed each other’s company, good food, games and rides. A wonderful time was had by all and a huge thank you goes out to all that participated in making this event possible.

O

ur last newsletter covered Pattern Engineering, Pattern Shop and Production Control. Phase 3 is focused on our Outside Sales Department. We currently have 2 outside salesmen. They are John Harvey and David Gangle. They work remotely from 2 other states. Wisconsin and Alabama. Below is a little bit about each one.

ur last newsletter covered Pattern Engineering, Pattern Shop and Production Control. Phase 3 is focused on our Outside Sales Department. We currently have 2 outside salesmen. They are John Harvey and David Gangle. They work remotely from 2 other states. Wisconsin and Alabama. Below is a little bit about each one.

John Harvey began his career in the foundry industry in 1995 at St. Marys Foundry, starting out in the cleaning room and, over six years, working through nearly every area of the foundry before finishing his time there in Sales. He went on to build his career across several well-known companies in the industry including Maynard Steel, Superior Graphite, Sivyer Steel, Elyria & Hodge Foundry and Matrix Metals Foundry Group. For the past 10 years, John has been part of the Benton Foundry outside sales team. John’s territory is mostly Mid-Western United States. John lives in Wisconsin with his wife Angie,. They have been married since 1998, have two children—daughter Lin and late son Connor. In his free time, John enjoys golfing and spending time with family and friends.

David Gangle has a BSME from the University of Akron and has worked for Benton since 2021 in outside sales. Dave had several years of experience selling heat treat equipment for Cronite, as well as, casting sales experience for Elyria Foundry.

He and his wife Justine have been married for 30 years and have two grown sons.  Dave resides in Birmingham, Alabama and works remotely covering customers in Southeastern United States.

Dave resides in Birmingham, Alabama and works remotely covering customers in Southeastern United States.

Outside of work, Dave enjoys all types of motorcycling, motor-sports and custom car shows.

The next phase will cover the Quality Department.

U

S manufacturing employment peaked in 1980 at nineteen million workers. In 2000, it still had seventeen million. Then it collapsed over the next decade, in part due to China, in part due to technology changes and especially after the global financial crises, when the workforce fell to just eleven million in 2010. In 2025, the United States has around thirteen million manufacturing workers.

At times, American elites have been strangely good humored about the departure of manufacturing jobs. In 1993, the chief economic adviser to George H. W. Bush, Michael Boskin, quipped “Computer chips, potato chips, what’s the difference?” It became part of the elite consensus that the United States could lose manufacturing. This consensus portrayed heterodox economists, as sentimentalists for resisting off-shoring. Neither the Clinton nor George W. Bush administration restrained American firms from moving manufacturing operations to China. Now, it’s more obvious that the departure of manufacturing has created economic and political ruination for the United States. We are still only beginning to understand how much it set the country back technologically.

~excerpt from Book on China “Breakneck” by Dan Wang whose basic premise is China is run by engineers and the USA by lawyers.

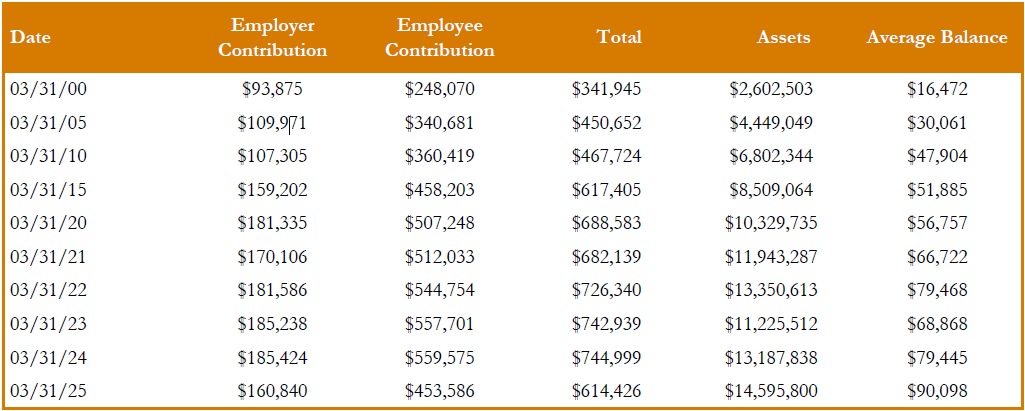

Benton Foundry gives you free money equal to 2.5% of your first 5% invested in our 401K, and you are vested after three years. If you are worried about losing money in the stock market, your account would have to fall by 33% or all the company’s contribution before you would ever lose any of your money. Below is a 25-year snapshot, showing the mutual funds average balance over time.

B

rock Smith, Benton Foundry’s Tooling Design Engineer, played a pivotal role in advancing the company’s metrology capabilities. His introduction to portable coordinate measuring arms began during his studies at Pennsylvania College of Technology, where he first used a Faro Arm.

He later gained additional experience with the technology during an internship. Early in his career at Benton Foundry, Brock attended a Pennsylvania Foundry Association meeting where he witnessed a live demonstration of the Hexagon Romer Arm. Impressed by its precision, speed, and versatility, he recognized its potential to improve Benton Foundry’s measurement processes.

In 2013, Benton Foundry made the strategic decision to purchase a Hexagon Romer Arm equipped with advanced laser scanning technology. This investment marked a significant step forward, providing a much faster and more accurate solution than the Brown & Sharpe CMM, which relied solely on single-point probing. The new system also allowed for more comprehensive analysis of complex geometries.

Building on that success, Benton Foundry recently upgraded to a 2025 model Hexagon Romer Arm and computer valued at approximately $100,000, trading in its 12-year-old model. Randy Kadtke and Xenia Ponce report that the latest version delivers about a 60% increase in scanning speed, can scan reflective surfaces without special preparation, captures data more effectively from deep pockets, and now offers improved feedback through Hexagon’s software. The Romer Arm plays a vital role in several key processes: wear reviews on patterns and core boxes after a specified number of machine cycles to monitor wear over time, dimensional layouts on newly sampled castings to ensure accuracy before production, and reverse engineering of castings to develop or refine tooling. It is also used to diagnose issues with both tooling and castings.

Hexagon’s advanced scanning and metrology solutions have made a global impact, with their technology contributing to the creation of some of the most complex structures in the world—most notably the $2.3 billion Las Vegas Sphere. Hexagon’s precision measurement systems ensured that massive steel components were fabricated and assembled with unmatched accuracy, enabling the Sphere’s unique shape and cutting-edge LED exterior to come together flawlessly. This same level of precision and innovation is now a part of Benton Foundry’s workflow, helping maintain its reputation for quality and consistency.

Hexagon’s advanced scanning and metrology solutions have made a global impact, with their technology contributing to the creation of some of the most complex structures in the world—most notably the $2.3 billion Las Vegas Sphere. Hexagon’s precision measurement systems ensured that massive steel components were fabricated and assembled with unmatched accuracy, enabling the Sphere’s unique shape and cutting-edge LED exterior to come together flawlessly. This same level of precision and innovation is now a part of Benton Foundry’s workflow, helping maintain its reputation for quality and consistency.

This continual investment in cutting-edge metrology tools demonstrates Benton Foundry’s commitment to quality assurance, efficiency, and staying at the forefront of manufacturing technology.

D

uring this quarter, Benton Foundry has lost four long-time employees to retirement. Although we are excited for them to begin the next chapter of their lives, they will be missed greatly. That being said, we wish the retirees many enjoyable years.

Ed Whitmoyer has retired after nearly 44 years of dedicated service. Early in Ed’s career, he was a manual and automatic molder. For the last 12 years, he worked in the Maintenance Department as a head electrician. Ed attended classes at Penn College to gain his electrical knowledge. Ed is quiet but known for his very dry sense of humor. He was one of three Whitmoyer brothers to work at Benton Foundry, along with his father-in-law, Roy Walters and his infamous brother-in-law, Galen Walters. Ed’s son worked on shakeout one summer and went to the University of Pittsburgh and attained a chemical engineering degree and now runs a major chemical plant. Ed lives in the Hughesville area with his wife, Deb. Ed will likely be spending more quality time with his wife, children and grandchildren now that he is retired. Ed also plans on learning to drive his son’s large boat on the Chesapeake. We wish Ed a long, healthy and happy retirement. Congratulations!

Mike Machuga has retired after 38+ years at the foundry. Mike has worked on the muller, operated core machines and most recently was an automatic molder. Mike excelled at any job he did. In the 1980s Mike ran the muller manually and was renown for the quality of his sand. He participated in many sand experiments. As a molder, he was also known for the quality of his work and was low in scrap for many years. His son, Brett also worked at the foundry before going on to be a dog handler for the PA Corrections system. Mike lives in Shickshinny with his wife, Rae Jean. He can now spend more time farming and hanging out with two other retirees, Mel Bartlow and Rick Wilson. We wish Mike a long, healthy and happy retirement. Congratulations!

Donna Remley has retired after nearly 38 years. Most of Donna’s years were spent in Inside Sales. Earlier in her career, she worked in the Payroll Department. Donna also produced the company newsletter (The Meltminder) for the last 13 years. Donna is known for a strict healthy living regimen that has carried over to other people in the office. Donna is also known for her shrewd financial acumen that is allowing her to retire at a young age. Her favorite numbers are 401K! Upon retirement, Donna plans to check off some of the adventures on her bucket list. Donna lives in Muncy with her significant other, Max and her Corgi, Riley. Donna has a daughter Kristina who worked at Benton Foundry while attending college. Donna’s father worked at Benton Foundry many years ago. We wish Donna a long, happy, and healthy retirement. Congratulations!

Steve Fritz is retiring after 15+ years. Steve worked admirably in the Melt Department performing ladle care and refractory work. Steve’s easy-going style served him well as an important cog, especially in light of the critical nature of refractory work. Steve and his wife, Kathy live on a farm on the road behind the foundry called “Fritz Hill” Road. The name Fritz has a long-term presence in the Benton area. Steve has a son, Ethan who is a Wilkes College Computer Graduate who continued his computer studies at Penn Tech while working in the IT Department at Benton Foundry. Steve raises sheep, horses and a variety of other animals. That will surely keep him busy upon his retirement. We wish Steve a long, happy and healthy retirement. Congratulations!

Good Luck & Best Wishes!

Thank you to Ed, Mike, Donna and Steve for your many years of dedicated service.

What root vegetable was traditionally used to carve Jack-O-Lanterns?

Answer will be in 4th Quarter 2025.

What is the longest river in the world?

Nile River

| Sergio Aguilera | Highest Foxall Uptime |

| Sergio Aguilera | Highest Grinding Efficiency |

| David Straub | Highest Molding Efficiency |

| David Straub | Highest Molds per Hour |

| Pete Gowin | Lowest Molding Scrap Rate |

| Nico Combarro | Highest Core Production Efficiency |

| Myriam Mayorga | Highest Core Assembly Efficiency |

Mike Newhart

Justo Guido

Angela Rodriguez

Yesslan Ruiz

Stanley Shuleski

Irlanda Aviles

Gene Burkhart

Aaron McHenry

Lester Urbina

Edwin Ramirez

Mike McDonald

Stephanie Selman-Guffey

Ed Gill

Carlos Moreira

Terry Whitmire

Pete Gowin

Jere Pirillo

Jarvin Barrientos

Gene Eckroth

Billy Green

Dave Buma

Ben Hatch

Maria Higgins

Greg Woodside

Julio Hernandez

Raul Armas

Gustavo Taveras

Guillermo Acevedo

Esperanza Rodriguez

Jeff Garrison

Jose Jesus Martinez

Wilmer Sanchez

Otilia Miranda

Jason Karcher

Thomas Zelinka

Gabe Keller

Lesbia Vargas

Kristhian Santos

Norlan Valdivia

Dave Hetler

Wilberth Lopez

Tim Miller

Cassandra Shoemaker

Jacqueline Artero

Teo Grigas

The yellow and orange colors you see on the trees in the fall actually always exist in leaves but they are overpowered by the abundance of green from chlorophyll. The amount of chlorophyll starts to decrease as the sun weakens and the days grow shorter.

Thank You to Annette Brown for all of her hard work in organizing the company picnic.

Congratulations to Chad Davis, Kyle Hall, Ana Ponce and Xenia Ponce for completing training requirements for GD&T Fundamentals.

Good Job to Matthew Herr for completing Intro-MECH MIDAS Apprenticeship Module through Penn Tech.

Thank You to Dave Buma for assisting with job fairs.

Congratulations to Ana Ponce and Xenia Ponce for completing UT and PT training through WTTI and for passing their exams!

Thank You to Elissa Romberger for assisting with the organization of the company picnic.

Great Job to Tamara Mabus for keeping all of the necessary “balls in the air.”

Thank You to Annette Brown for organizing the PHS appointments and for her professionalism with the PHS Staff.

Good Job to Nico Combarro, Kris Young and Irlanda Aviles for becoming solid core machine operators.

Great Job to Stan Shuleski for completion of the AFS Intro to Supervision course and for your ongoing training for night shift Grinding Room Assistant Supervisor.

Thank You to Andy Spencer, Gabriel Lopez, and Gilberth Mayorga for your versatility helping in 3 different departments.

Good Job to Chris Diltz for the extra effort, willingness to learn and for being able to think outside the box.

Thank you to Dave Buma for taking on extra responsibilities with truck runs and non-rolling stock repairs.

Great Job to Lynn Miller, Brock Smith, Cody Bown, the pattern shop, the quality department and the Foxall fixturing crew for ramping up all of the jobs this quarter as a result of struggles at a neighboring foundry.

Thank you to Nate Steinruck and Colton Young for extra technical help and providing on-call support as needed

Great Job to Timmy Schechterly for helping execute large/complex repairs.

Thank you to Matt Herr for helping straighten out the cranes and for tackling many welding/fabrication projects.

Good Job to Kevin Trychta for training completed through Pennsylvania Rural Water Association.

Great Job to Ramiro Pomares Cortes for being an efficient and reliable lab tech as well as training other lab personnel.

Thank you to numerous production employees that routinely help with maintenance tasks when not needed in their home departments.